IPEM

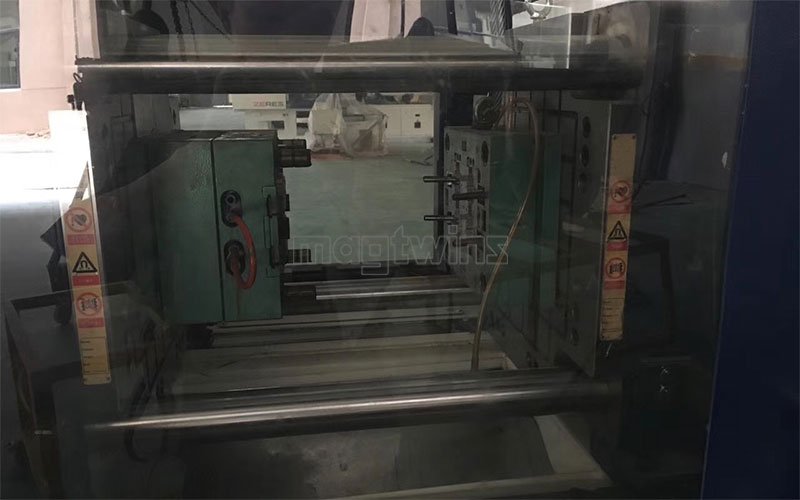

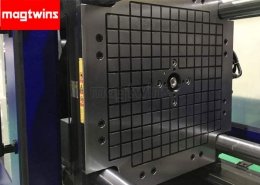

IPEM Magnetic Platens Injection Molding is the advanced technology for mold change of IMM machine(injection molding machine). It use the Permanent Magnetic platens to replace traditional clamps systems, and could provide much better efficiency and accurancy.

FEATURES

APPLICATIONS

Quick mold change of IMM(injection mold machine), Press machine and Die Spotting Machine